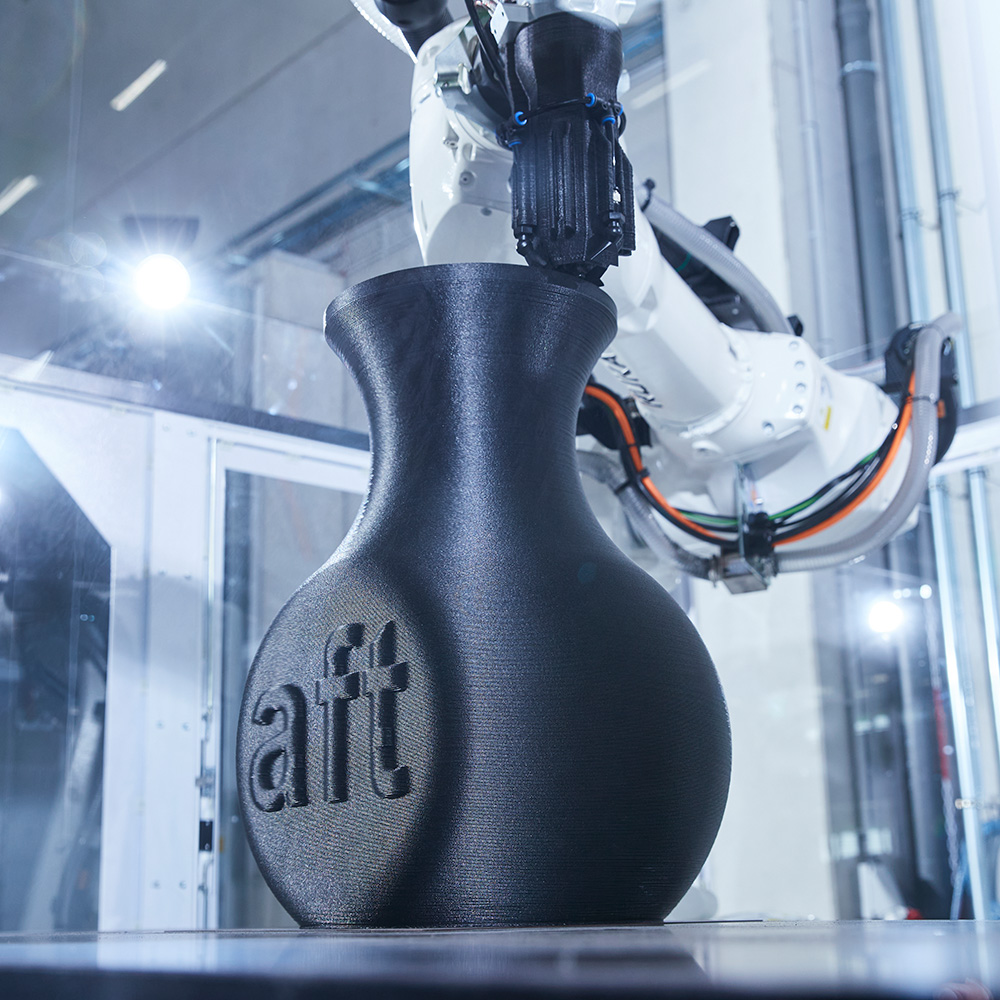

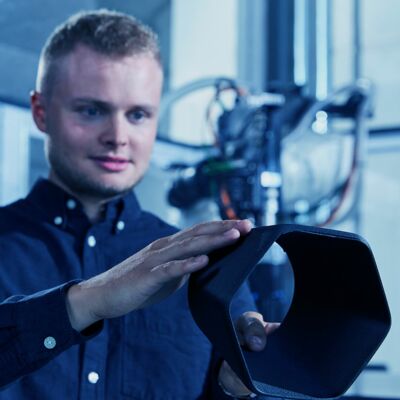

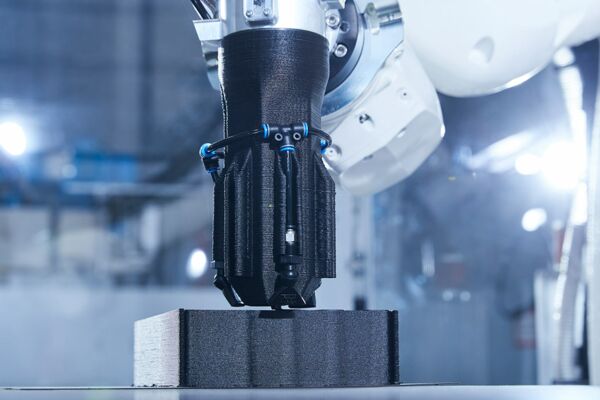

As a system supplier to the automotive industry, we manufacture complex functional components and piping systems for media routing and media control. This wealth of experience now also shapes our Fused Layer Modelling (FLM). After all, just like in injection moulding, the process involves heating and cooling plastic. Our experts ensure that all 3D processes are perfectly “guided” and precisely controlled.

Have any questions?

+44 1234 567 890